Key features and applications of beryllium copper

2023-10-17

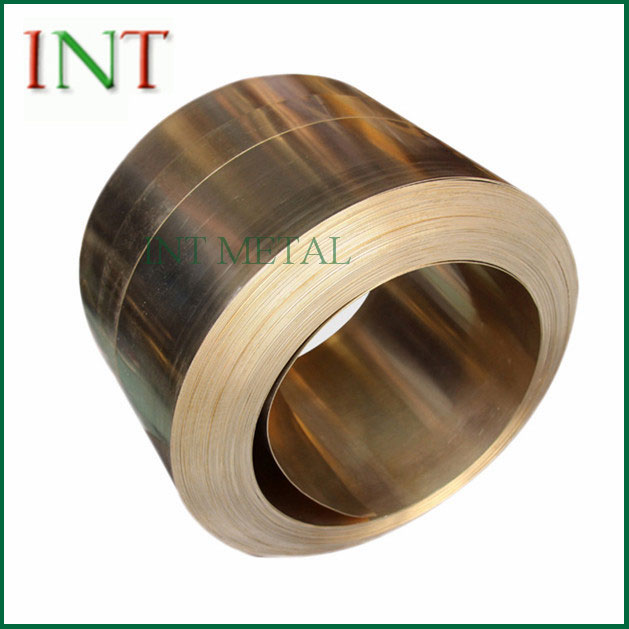

Beryllium copper, often abbreviated as BeCu or beryllium bronze, is a copper-based alloy that contains a small percentage of beryllium (Be). This alloy is known for its unique combination of properties, including high strength, excellent conductivity, and good thermal conductivity. Beryllium copper is widely used in various industries, particularly where these properties are essential. Here are some key features and applications of beryllium copper:

Key Features:

1. High Strength: Beryllium copper exhibits remarkable strength, particularly in the age-hardened condition. It is one of the strongest copper-based alloys, with tensile strengths comparable to many steel alloys.

2. High Conductivity: While not as conductive as pure copper, beryllium copper still maintains good electrical conductivity, making it suitable for electrical and electronic applications.

3. Good Thermal Conductivity: Beryllium copper also has excellent thermal conductivity, which is important in applications where heat dissipation is critical.

4. Corrosion Resistance: It offers good resistance to corrosion in various environments, although not to the extent of pure copper.

5. Spring Properties: Beryllium copper alloys are known for their spring-like properties, allowing them to be used in components requiring reliable and long-lasting spring action.

6. Non-Sparking: Certain beryllium copper alloys are non-sparking, making them ideal for use in environments where sparks could pose a safety hazard, such as in oil and gas industries.

7. Machinability: Beryllium copper is generally machinable, although the presence of beryllium can make it more challenging to machine than pure copper.

Applications:

Beryllium copper is used in a wide range of applications across various industries, including:

1. Electrical and Electronic Connectors: Beryllium copper's combination of electrical conductivity and strength makes it suitable for connectors, switches, and sockets.

2. Springs and Contacts: Its spring-like properties and resistance to fatigue make it ideal for use in various spring applications, such as electrical contacts and switches.

3. Aerospace and Aviation: Beryllium copper is used in aircraft components, such as landing gear parts, bushings, and bearings, due to its strength and corrosion resistance.

4. Oil and Gas Industry: In environments where sparks could trigger explosions, non-sparking beryllium copper tools and equipment are used, such as wrenches, hammers, and drilling tools.

5. Plastic Injection Molding: Beryllium copper is used in injection molds and tooling components for its high thermal conductivity and wear resistance.

6. Automotive: It finds applications in automotive components, including valve seats, springs, and gaskets.

7. Electronic Enclosures: Beryllium copper is used in electronic enclosures and shielding due to its electrical conductivity and ability to dissipate heat.

8. Military and Defense: It is used in various defense applications, including connectors, ammunition components, and safety tools.

9. Telecommunications: Beryllium copper connectors and terminals are commonly used in the telecommunications industry.

It's important to note that beryllium is a toxic element, and the production and handling of beryllium copper alloys must adhere to strict safety guidelines to protect workers and the environment. Special precautions are taken during machining and processing to prevent beryllium exposure. Additionally, recycling of beryllium copper scrap requires careful handling and processing to ensure safety.