Several types of oil-free vacuum pumps available

2023-10-17

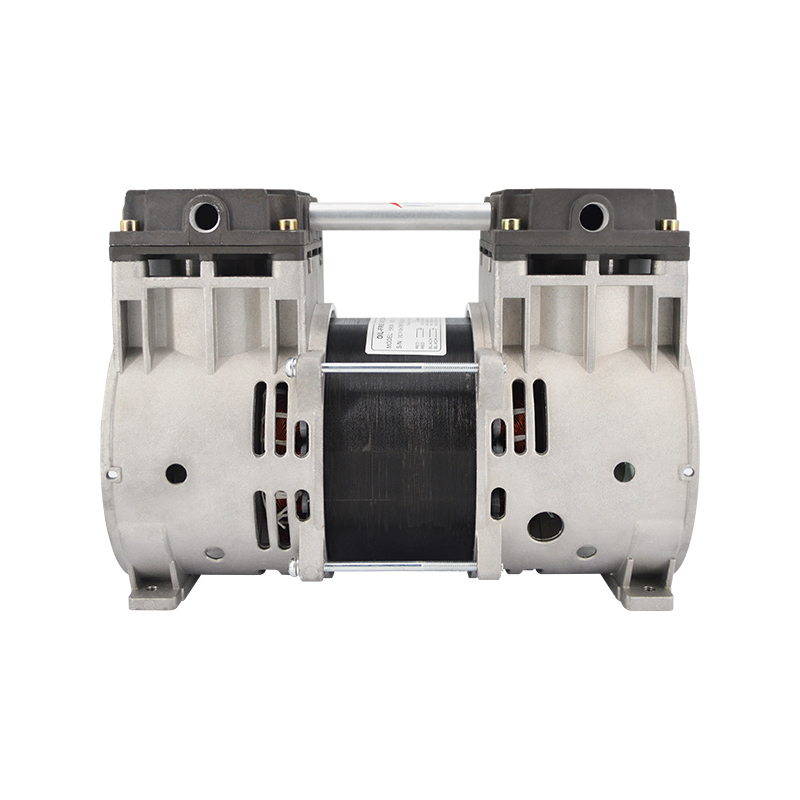

An oil-free vacuum pump, also known as a dry vacuum pump, is a device used to create a vacuum or negative pressure without the use of oil as a lubricant or sealing medium. Unlike traditional vacuum pumps that require oil for lubrication and sealing, oil-free vacuum pumps employ alternative technologies to generate vacuum without oil contamination. These pumps are commonly used in applications where oil-free operation is crucial, such as in laboratories, medical facilities, semiconductor manufacturing, and other sensitive environments.

There are several types of oil-free vacuum pumps available, including:

1. Diaphragm Pump: Diaphragm pumps use a flexible diaphragm to create a vacuum by reciprocating the movement of the diaphragm. The diaphragm acts as a barrier between the vacuum chamber and the drive mechanism, eliminating the need for oil lubrication.

2. Scroll Pump: Similar to oil-free air compressor pumps, scroll pumps can also operate as oil-free vacuum pumps. These pumps use two interlocking spiral scrolls to compress and pump air, creating a vacuum. The scrolls do not require oil for lubrication, enabling oil-free operation.

3. Claw Pump: Claw pumps use a pair of interlocking claw-shaped rotors to create a vacuum. The rotors spin in opposite directions, trapping and compressing the air between them. The design of claw pumps eliminates the need for oil lubrication.

4. Multi-stage Roots Pump: Roots pumps, typically used in combination with a backing pump, can be configured to operate as oil-free vacuum pumps. These pumps use a pair of intermeshing rotors to pump air, and by removing the need for oil lubrication, they can be operated in oil-free mode.

Oil-free vacuum pumps offer several advantages, including:

1. Contamination-free: Since there is no oil involved in the pumping process, oil-free vacuum pumps eliminate the risk of oil contamination, making them suitable for applications that require a clean and pure vacuum.

2. Low maintenance: Oil-free vacuum pumps generally require less maintenance compared to oil-lubricated pumps. There is no need to monitor or replace oil, and there is a reduced risk of oil leaks.

3. Environmental friendliness: Oil-free vacuum pumps are more environmentally friendly as they eliminate the use of oil and the associated disposal concerns.

It's important to select an oil-free vacuum pump that meets the specific requirements of your application in terms of desired vacuum level, flow rate, pressure range, and compatibility with the gases or vapors being evacuated. Consulting the manufacturer's guidelines and specifications will ensure the proper selection, installation, and maintenance of the oil-free vacuum pump for optimal performance.